Warehouses and industrial buildings will often have a large amount of goods, which may be stacked on racks or shelving systems, up to the ceiling. Even this may maximise space, but it also substantially doubles fire risks – especially if hazardous or combustible materials are stored. That is when high-piled storage plays its role.

This is the point where ComplianceFirst takes over the job, providing the high-piled permitting expert services to guarantee that your facility meets the national and local life safety standards.

Why High-Piled Storage Requires Special Permitting

First of all, high-piled combustible storage, according to the International Fire Code (IFC), refers to the materials stored in tightly packed piles or on racks more than 12 feet high (or even 6 feet for hazardous materials).

Why is that important?

- Tall stacks create vertical fire paths.

- Sprinkler systems may be obstructed or ineffective.

- Fire department access becomes more difficult.

- The presence of hazardous materials adds chemical and combustion risks.

Planning the storage of materials at such heights implies you are mandated by the law to get a High-Piled Combustible Storage Permit with the local Authority Having Jurisdiction (AHJ) where you are situated.

Step 1: Understand Your Inventory’s Risk Level

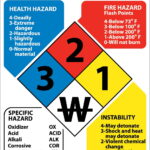

The initial step to securing a high-piled storage permit is a precise knowledge of the items that are stored and the level of hazard associated with them. Chemical classifications are indispensable in this context, especially when the substances are:

- Flammable or combustible liquids

- Aerosols or oxidizers

- Corrosive or reactive chemicals

- Pressurized gases

Each chemical has a hazard class depending on physical and health-related risks. These classifications set:

- The requirements of your permit

- The suppression or sprinkler systems you need

- The necessity for ventilation, signs, and even the width of aisles

This is the primary reason why our hazard chemical classification services represent the basis for a correct permit filing.

Step 2: Ensure Hazardous Material Compliance

Once all your materials have been classified, the second critical step is the demonstration of compliance with the fire and life safety codes.

The Core Areas of Hazardous Material Compliance Are:

Sprinkler Design & Fire Suppression

Your storage design must be such that it provides for effective fire detection and suppression. In-rack sprinklers, higher water flow rates, and the use of extended heads for coverage may be some of the requirements.

Storage Configuration & Aisle Spacing

The correct spacing between the pallets and the racks is what assures that a fire can be efficiently contained and put out in a short time. Going beyond the volume or height limits without proper grounding usually will result in permit denials.

Access & Egress Planning

The emergency response personnel must have effortless and direct access to the high-pile storage areas. Blocked exits or narrow paths are at the lower end of safety violations.

Fire Department Pre-Planning

AHJs often require the fire departments to be very familiar with the location, risk levels, and access points of your facility. ComplianceFirst collaborates with clients from various industries to streamline hazardous material compliance, thus reducing the risk and raising the chances of rapid permit approval.

Step 3: Submitting for High-Pile Permit Approval

One is allowed to apply for the permit once the materials are classified and the facility meets the fire code regulations. Standard Documents Required to Provide Include: Inventory report with hazard classifications, Floor plan with rack layout and height, Sprinkler system design drawings, Fire protection system specifications, Emergency access plan, Control area separation strategy (if needed). A mere mistake or omission in these documents might postpone the approval or cause the documents to be rejected. The service that we offer in high pile permitting service removes the uncertainty from the equation.

Common Challenges in High-Piled Permitting

While each project is different, there are several typical problems that we solve for our clients over time. These include:

Lack of accurate inventory classification, Non-compliant sprinkler systems, Improper storage layouts, Inadequate fire detection equipment, Outdated facility documentation, Multiple control areas without proper separation. If you are not aware of how your facility is operating, our team can conduct a gap assessment and provide practical recommendations to consider before you apply.

Why Partner with ComplianceFirst?

There is no place for shortcuts if safety and code compliance are the issues. High-pile storage permitting is complicated and is constantly changing. The benefits of working with the help of professionals include faster approvals, a safer work environment, and long-term compliance. We, at ComplianceFirst, offer:

- End-to-end permitting support

- Expertise in hazardous material classification

- In-house code specialists and fire protection engineers

- AHJ coordination and documentation prep

- Customized strategies for your specific risk level

Need Help Navigating High-Pile Permits?

Whether you are erecting a new warehouse, increasing your business, or unloading new materials, first and foremost, do not let compliance be a matter of chance. Please get in touch with ComplianceFirst for reliable direction and zen-like reassurance. Our team’s experts are always ready to assist you in simplifying the complicated process and obtaining your permit without holding up your progress.

Contact us right now to plan a consultation where we can talk more about how we can help you with your industry's high-piled storage compliance.