When storing hazardous materials, it’s imperative to understand their properties, interactions, and possible dangers. Many warehouses, pharmaceutical companies, and other professional entities need to know the classification of their stored chemicals. In addition, understanding what you have in your inventory is a legal requirement for passing code and ensuring that your business is up to standard. Imagine the liability that would ensue if something disastrous occurred!

A chemical inventory classification consultation will help to avoid unnecessary dangers. Regulatory compliance and inventory maintenance is required for a safe and smooth operation. In order to comply with these standards, keeping an up-to-date inspection is required.

Inventory is Required

When storing chemicals, it’s imperative to keep your materials up-to-date and labeled. Imagine leaving an unlabeled hazardous material open and a blissful new employee mixes it with something incompatible. A dangerous act could have been avoided if a system of organization is initiated through a chemical inventory classification. Keep a list of your inventory so you can know what you have on hand and what is needed for the future. This keeps your in-house inventory up-to-date and organized. In addition, materials that aren’t needed need to be disposed of properly. This is why a professional chemical inventory inspection is needed; it helps you avoid a harmful and disastrous occurrence.

Labeling Protocol

Often times, labs and other professional entities will remove the chemical from its original container and place it into something different. Although this should be avoided, in order to keep things organized, a detailed label should be placed on the container. This should include the contents, name, and usage. If the item is indeed hazardous, make this known with a clear and distinct label. Chemical inventory classification helps ensure all employees know which chemicals require which labels. This makes it easy for others to know which chemical needs special handling.

Chemical Storage

How you store various chemicals depends highly upon its context and chemical properties. Certain materials need to be kept separate from others to avoid a possible chemical interaction. Although it may seem ideal to organize your items alphabetically, often times that can result in a disastrous outcome. Instead of storing them based on their names, focus on classification and usage. Store items that have compatible properties together so as to avoid fire or a toxic environment. For example, oxidizers should be kept separate from chemicals that could result in combustion. Acids should be kept separate from metals since their interaction could create a fire.

Separation involves more than just storing your items on different shelves. Chemicals whose interactions could be disastrous should be separated by a wall or other blocking material to ensure that nothing interacts. Closed and locked cabinets are preferred as they cannot mix. In addition, flammable materials are the most imperative to focus on as their mixture could result in disaster. Therefore, store these in containers or locked cabinets.

Implement Hazard Class Rules

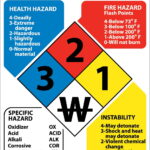

As mentioned, many chemicals cannot be stored or exposed to others as it can result in fire or high toxic levels. In addition, there are various levels of hazardous materials that must be kept in mind. When a chemical belongs to a specific family or class, it’s imperative to observe the rules associated with corrosive and combustible properties. These items should be separated to ensure no destructive interactions take place. Chemical inventory classification is important when it comes to identifying these hazards so you can take the necessary precautions.

Inventory Storage Tips

When storing these materials it’s important to know the do’s and don’ts of storage. All storage spaces must be labeled, clear for walking, and kept in a well-lit environment. However, exposure to extreme heat should be avoided such as severe sunlight, HVAC systems, and other flammable materials. If an accident should occur, all chemicals should be cleaned immediately and not poured into sinks or drains. This could create a host of problems for your plumbing system and expose the public to harmful chemicals. Chemicals should not be stored on the floor but rather on an elevated shelf. Cabinets should be approved by professional code consultants to prevent possible damage. As always, approved cabinets with dangerous materials should be labeled. A chemical inventory classification is needed to ensure that hazardous materials are being stored properly. Having a professional consultant evaluate your operations helps ensure that your facility is operating safely.