If your business handles or stores hazardous materials for any length of time, safety is a concern for you. Federal regulations require you to have H Occupancy Design permits. There are guidelines to follow and plans to document and enact. The entire process is simplified with the help of an expert consultant. Here are a few of the steps you will have to take.

Know Your Limits

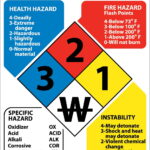

There are basic limits on how much hazardous material you can store in a given location without reporting them. Generally, hazardous liquids are limited to 55 gallons. Solid materials are limited to 500 pounds. Compressed gases must be reported if they exceed 200 standard cubic feet of compressed gas. You will need a hazardous materials inventory statement that may include materials such as: new and used oil, gasoline, diesel fuel, propane, antifreeze, solvents, and compressed gases. Having a hazardous materials inventory statement is essential to obtaining hazardous materials permitting because not all materials are considered equal. Some are classified as physical risks while others are considered health risks. They are categorized on a scale from H-1 (highly volatile) to H-5 (Least volatile).

Build to Store Accordingly

Storing hazardous materials of different types requires different building structures. For instance, H-1 materials in Type IIIA buildings may be a single story and 9,500 sq. ft. of area per floor. However, if that same building has a Group B occupancy categorization, than it is permitted to be five stories in height and 23,500 sq. ft. of area per story.

Storage Containers

The most common code violation regarding hazardous materials is improper storage containers and improper labeling. It is essential to know the codes and have clear communication of them throughout your business. Labels must be legible and up to date. Lids on canisters need to be secured tightly. They should be placed in a way so that they cannot fall upon each other

Have an Emergency Plan

Accidents happen. You need to have a plan for what to do in case of spills, leaks, or explosions. This plan needs to be determined by your H occupancy design, your hazardous materials inventory statement, and should be vetted by experts when you apply for hazardous material permitting.

Get your hazardous material permits

Where do you get your hazardous material permits? Check with your local Fire Marshal for the required form in your area. There are fees associated with the Planning office, Building Inspection office, Fire Marshal’s office, and possibly the Land Development and Surveyor’s office. This may vary from one region to another, but the bottom line is, this is not a simple endeavor. There are multiple points of accountability to ensure the safety of your business. This can be a lot of paperwork to get through to obtain your h occupancy permits: hazardous material classification, hazardous materials inventory statement, etc. Before you hire a lawyer to help you file the paperwork, consider working with a consultant on your H Occupancy design.

Consult with a H Occupancy Design Expert

The most efficient and all-around best way to get hazardous classification permits is to consult with a hazardous materials expert. They know the process inside and out and can help make the best use of your time and money in acquiring your H Occupancy Design permits. They also know the reasons behind the regulations which gives you the assurance that your facilities will be as safe as possible. This gives you the credibility to claim safety as a top priority in your business, which can be shared with, and through your employees, and with your customers as well.

Safety should be a core value of your business, especially if you are working with hazardous materials. If you want it to be more than words on paper, seek out expert consulting on your H Occupancy Design.